จากเลย์เอ้าท์ชุดไฟเลี้ยงของC2จุดนั้น

Cฟิลเตอร์หลัก(ค่าสูง)อยู่ห่.างไปหน่อย บางช่วงลายทองแดงมีการจั๊มลายข้ามชั้นบนชั้นล่าง

ถ้าไม่ใช้ค่า0.1uFจะใช้ค่า1uF เพื่อชดเชยเส้นทางของลายทองแดงก็ได้ครับ ถ้ามือนิ่งพอก็บัดกรีขาCที่ขา1798เลยครับ

จริงๆอยากแนะนำให้ใช้1uFน่ะ ถ้าใช้ของEROได้ก็ดี เพื่อชดเชยเสียงบางอย่างของตระกูลburr-brown

(ความเห็นส่วนตัว -- ถ้าหาSprague Silver Micaรุ่นเก่าๆได้ และไม่สนใจเรื่องขนาดที่มันใหญ่โตมโหฬารก็น่าลองดู

เหมือนกัน)

ถ้าจะเน้นตัวเล็กๆแต่ทำงานได้ตรงตามหน้าที่ก็ใช้ชนิดMultilayer Ceramic Capacitorก็ได้ รูปร่างกับขนาดก็คล้ายๆvishay vshครับ

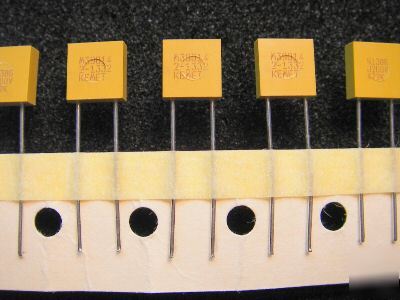

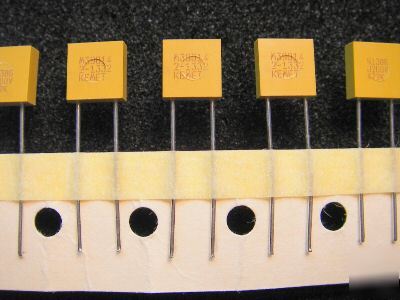

เกรดดีหน่อย (Low inductance and undetectable ESR) ก็หน้าตาแบบนี้

-------------------------------------------

Rรุ่นนี้ก็ใช้ได้ครับ แต่ควรใช้แบบตัวเดียว หลีกเลี่ยงการต่อแบบอนุกรมหรือขนาน

vishayรุ่นนี้เสียงจะบางหน่อย

Cฟิลเตอร์หลัก(ค่าสูง)อยู่ห่.างไปหน่อย บางช่วงลายทองแดงมีการจั๊มลายข้ามชั้นบนชั้นล่าง

ถ้าไม่ใช้ค่า0.1uFจะใช้ค่า1uF เพื่อชดเชยเส้นทางของลายทองแดงก็ได้ครับ ถ้ามือนิ่งพอก็บัดกรีขาCที่ขา1798เลยครับ

จริงๆอยากแนะนำให้ใช้1uFน่ะ ถ้าใช้ของEROได้ก็ดี เพื่อชดเชยเสียงบางอย่างของตระกูลburr-brown

(ความเห็นส่วนตัว -- ถ้าหาSprague Silver Micaรุ่นเก่าๆได้ และไม่สนใจเรื่องขนาดที่มันใหญ่โตมโหฬารก็น่าลองดู

เหมือนกัน)

ถ้าจะเน้นตัวเล็กๆแต่ทำงานได้ตรงตามหน้าที่ก็ใช้ชนิดMultilayer Ceramic Capacitorก็ได้ รูปร่างกับขนาดก็คล้ายๆvishay vshครับ

เกรดดีหน่อย (Low inductance and undetectable ESR) ก็หน้าตาแบบนี้

-------------------------------------------

Rรุ่นนี้ก็ใช้ได้ครับ แต่ควรใช้แบบตัวเดียว หลีกเลี่ยงการต่อแบบอนุกรมหรือขนาน

vishayรุ่นนี้เสียงจะบางหน่อย

)

)

Comment